Advanced designs - High quality products - Excellent service and assistance: this is

what distinguishes Binet Sul Liri. Every felt produced by Binet Sul Liri is customized

according to the customer's needs in order to optimize the performance and output

of a specific paper machine.

Perfect seam-felts, tissue felts for very high speed paper machines, felts with very high

void volume for shoe-presses, up to very special marking felts represent the range of

Binet sul Liri’s production.

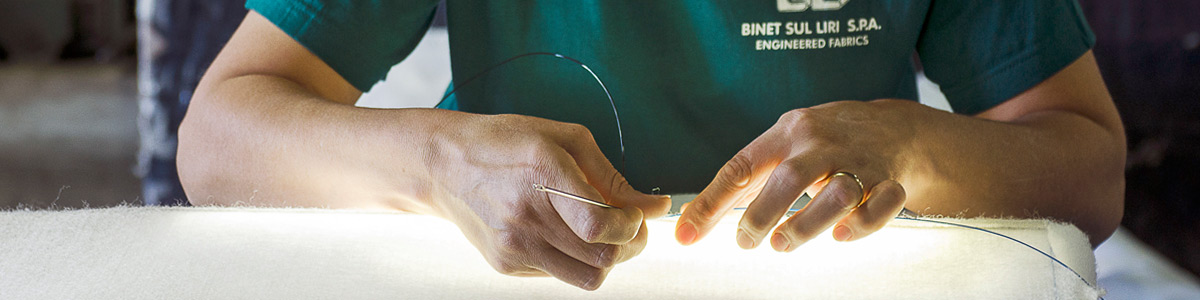

Two thousand needles per meter of width penetrate at a rate of 600 strokes per minute into the pre-needled veil so to fasten it with an exclusive formula to the base fabric.

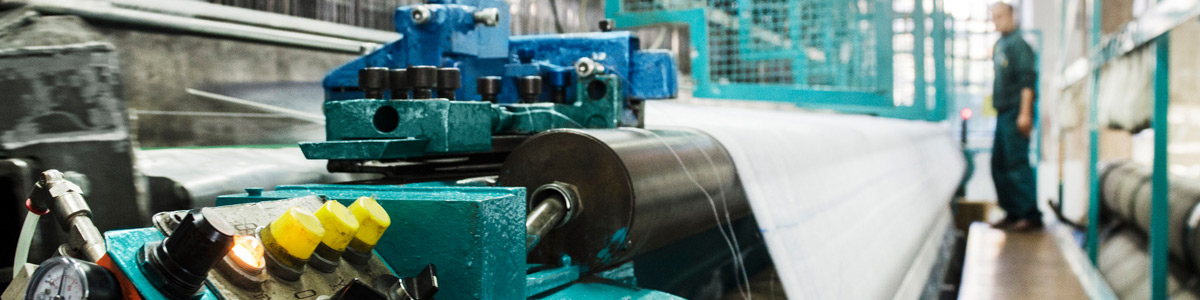

Six weaving looms from 9 to 20 meters of reed width for felts that can reach up to 80 meters down to small marking felts of 5 meters for endless or seam felts.

The production-cycle of each felt ends with the calandering of the product which consists in the heat-setting, the pre-compaction, the edge welding and a scrupulous checking of the main functional parameters.

Flat and Round monofilaments, density until 340 yarns/10cm2, air permeability from 80 up to 800 cfm, reduced thickness, high-quality raw-materials characterize our BINPERM or BINPLANE.

Gripple-shuttle weaving looms, hydraulic peaking, high automation ensure a perfect and reliable production.

Manual skills and mechanical precision permit us to obtain perfect seams in the microspiral, minispiral and pin-seam types.

Also for dryer screens, the production-cycle ends on the calander where the fabric is stretched and heated at a high temperature in order to obtain its heat and mechanical stability.